|

WENZHOU JIESHI GLASSES CO.,LTD

|

2014 NEW DESIGN SUNGLASSES FOR WOMEN

| Price: | 5.0~10.0 USD |

| Payment Terms: | T/T,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No: 9044S

SIZE: 60-15 132

LEN`S MATERIAL: POLARIZED LENS OR AC LENS

QUALITY: FDA and CE

FACE SHAPE MATCH: WOMEN

PACKING: 1 PC/HARD CASE

THE FEATURES:

Fashion design PC sunglasses

Polarized lens or AC lens for selection

light frame make you feel comfortable

good quality

Ready stock to offer

Special packing details

different packing hard case for your choosing

PACKING OPTIONS 1:

PACKING OPTIONS 2:

OUR ADVANTAGES:

1. We have own brand-AGADA and ABC

2. We offer ready stock for many styles with small MOQ

3. Each month we have around 5~10 new models offer

4. Small order and mixed order is accepted

5. We have a short delivery time. Especially for ready stock will be effected within 1 week.

6. OEM is welcome

F.A.Q.:

1.Could I put my own logo on the optical frames?

---Yes, of course, customer`s logo can be made by printing, laser ,engraved,embossed etc.

2. How about the quality

---Meet CE ,FDA

3.Could I buy 1 pc sample first?

---yes, sample order are supported

4. How many days you need for samples?

Could I put my own logo on samples?

---within 5 days if we have stock

---The logo should be printed only

MANUFACTURING PROCESS:

Frames&Temples:

First the frame are made of plastics, after made out from the mould, they will be put on the polisher for polishing one piece by one piece, so it will become more sleek.

Hinges :

All the frames have optical quality hinges fixed with screws as opposed to rivets. Half of the hinge will be put into the frame before dye the frame, another will be welded on the temple, then they can be jointed together by a screw.

Screws:

All the screws are made of nickel silver

Dying:

The frames will go through a dying system, which can put the color on the frames as planned. After the basic color, it will also go through a Lacquer Coating Procedure. By doing this, it will make the color stronger and last for longer time.

Lenses:

We use first quality polarized lens and un breakable acrylic lens

Cutting & fitting of lenses:

The lenses are carefully cut by the cutting machine which is operated by specialized optician staff. By using the focometer, it will ensure all the cut lenses will comply with the Pupil Distance requirement. Then the cut lenses are fitted into the frames by the skillful and well experience workers. Special attention will be paid for the cutting lens, fitting process. The alignment will be also very important.

QUALITY CONTROLLING PROCESS:

All material we use are no-allergic. It`s the standard for the European Countries. During the production, several control test are normally executed. The quality inspectors will inspect every production process and deliver comments and instruction if necessary.

Before dying:

The workers will check all the frames in one by one basis. All failed frames will be rejected and re-work by the original procedure department.

Before fitting up of lenses:

The workers will also check frames in one to one basis. All frames must be perfect made before we fit the lenses

Control of lenses when we put the power adhesive on the left lenses

The diopter of the lenses will be checked by the lenosmeter before the lenses was fitted to the frames

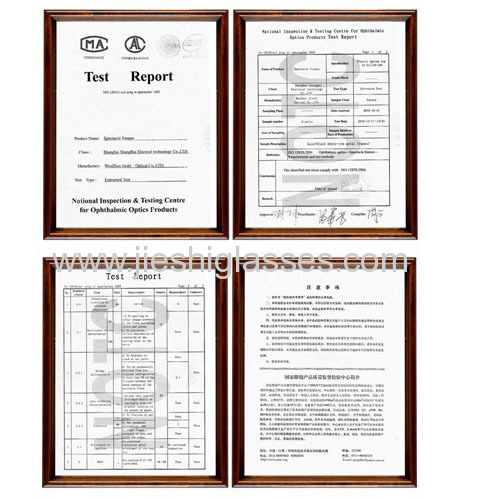

CERTIFICATION:

FACTORY SHOWS:

MANAGER:

CONTACT US: